Product Features

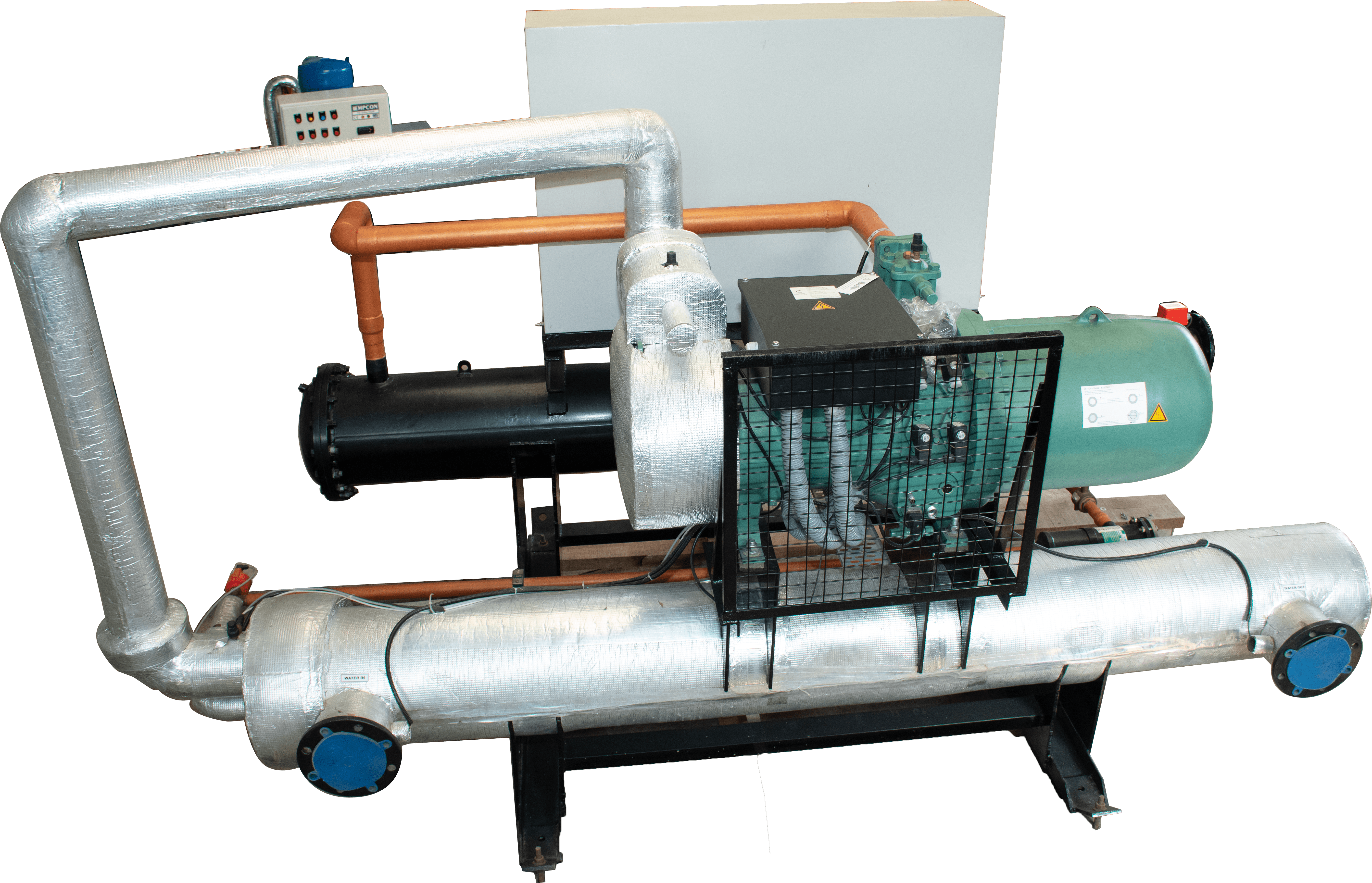

Our brine chillers have a robust, self-standing painted steel frame. It provides a stable foundation for years of dependable operation.

You can choose from one of the following compressor types:

-

- Version-A: Semi-Hermetic Reciprocating Compressor

- Version-B: Scroll Compressor

- Version-C: Open Type Screw Compressor

You can even choose the type of refrigerant that aids the cooling process. Your options are R40Aa, Ammonia, or CO2.

- Versatile Condenser Choices

Adapt to your cooling needs with different condenser options.

-

- Version-A: Water-cooled chillers use a shell & tube condenser for optimal closed-loop cooling efficiency.

- Version-B: Air-cooled chillers use a fin & tube condenser for a cost-effective, space-saving solution.

- Version-C: Brine chiller uses an evaporative condenser for maximum cooling capacity in harsh environments.

- Evaporator Options

To achieve optimum cooling efficiency, we have kept your options open for the type of evaporator in your brine chiller.

-

- Version-A: Shell & Tube Evaporator for efficient heat exchange for larger applications.

- Version-B: A tube-in-tube type evaporator for compact design and high-pressure capabilities.

- Version-C: SS Plate Type Heat Exchanger for superior corrosion resistance and easy cleaning.

- Process Pump

We use a stainless steel process pump to minimize rusting and corrosion in the pump. This high-prevalence pump ensures the long lifetime of the glycol chiller.

Most low-temperature chillers require precise and accurate temperature control. That’s why we use electric heaters with modulating valves for accurate temperature control of +/- 0.3°C. Plus, the microprocessor having a PID function enables more precise control.

Conformité Européenne (CE) and Pressure Equipment Directive (PED) Certification make Tempcon the best brine chiller manufacturer in India.

Tempcon ensures that all the brine chillers comply with the Eco Design Directive. This makes them eco-friendly, and thus, they leave a lower carbon footprint. We are giving you a chance to make the responsible choice for your cooling needs.