A Complete Guide To Industrial Chiller – Types, Application And Selection

This industrial chiller guide explains types, applications & selection criteria. Learn how to choose the right cooling solution for your manufacturing process.

Every industry needs a proper thermal management system at a certain scale. In most cases, the level of precise temperature control requires an advanced setup called an industrial chiller.

In this guide, we will find out what these industrial chillers are, their types, and their applications. We will also assist you in finding the best industrial chiller for your industrial cooling requirements.

What is an Industrial Chiller?

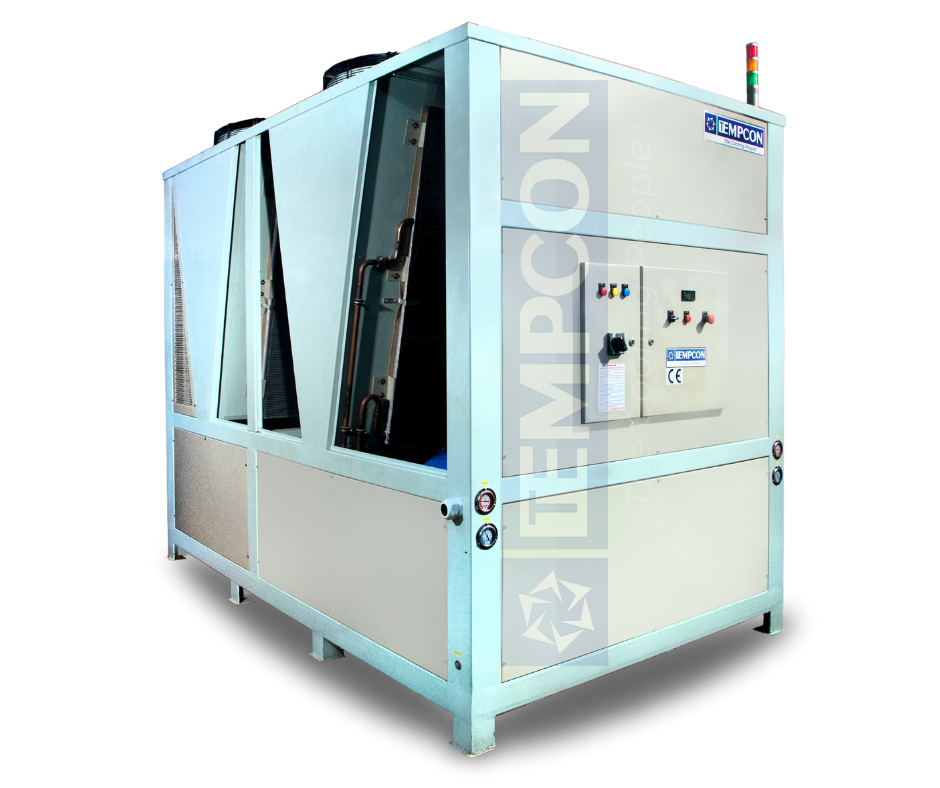

An industrial chiller is a specialized refrigeration system installed on an industrial premise. This machine runs on coolants like air, water, glycol & brine, etc.

These machines are designed to meet a high industrial cooling demand that normal air conditioning systems cannot provide. They are designed to operate constantly even under heavy loads without compromising the control over temperature.

Key Components

- A compressor

- A condenser

- An expansion valve

- An evaporator

- A smart control panel system, etc

Industrial chillers function by circulating the chilled fluid through process equipment or production lines. This fluid then absorbs heat and returns to the chiller where the heat is removed and released externally. This process repeats the entire time a chiller is operating in an industrial setup.

Types of Industrial Chillers

These modern industrial chillers come in various configurations in terms of cooling operations and components. Such variation in an industrial chiller design offers unique advantages along with industrial applications.

Here is the list of modern industrial chillers Tempcon offers.

Glycol & Brine Chillers

These chillers use glycols as coolants. They provide cooling capacity from 1TR to 100TR and can operate at temperatures from -40°C to +4°C.

- Compressor Options: Semi-hermetic reciprocating, scroll, or open-type screw compressors

- Refrigerant Options: R40Aa, Ammonia, or CO2

- Condenser Choices: Water-cooled shell & tube, air-cooled fin & tube, or evaporative condenser

Industrial Reciprocating Chillers

These chillers offer wide temperature control (-40°C to +4°C). The modern designs are available with either semi-hermetic or hermetically-sealed reciprocating compressors.

- Frame: Stainless steel self-standing structure with protective paint coating

- Compressor Types: Semi-hermetic reciprocating or hermetic sealed reciprocating

- Refrigerant Options: Environmentally friendly R40Aa, Ammonia, or CO2

Variable Frequency Drive (VFD) Chillers

These VFD chillers offer excellent control over cooling efficiency while minimizing environmental impact. They provide cooling capacities from 5TR to 350TR.

- Frame: Modular design with galvanized steel and epoxy-polyester powder coating

- Compressor: Energy-efficient scroll compressors using R410a refrigerant

- Capacity Control: Stepless capacity adjustment from 10% to 100% via VFD technology

Applications of Industrial Chillers

An industrial chiller is chosen based on the industrial applications. Not all chillers set the parameters right. It depends on the equipment, industrial processes, temperature range, and temperature control. Here is the list of industries where chillers are used.

Plastic Manufacturing

- Injection Molding: Maintains consistent mold temperatures

- Blow Molding: Ensures uniform wall thickness

- Film Extrusion: Controls cooling for uniform thickness

- Compressed Molding: Regulates temperature for optimal curing

Pharmaceutical Industry

- API Manufacturing: Ensures chemical stability

- Laboratory Processes: Maintains precise temperatures

- Processing Equipment: Prevents heat-related degradation

Food and Beverage Production

- Dairy Processing: Controls temperatures for pasteurization

- Edible Oil Manufacturing: Prevents degradation

- Breweries: Ensures consistent fermentation temperatures

- Carbonated Beverage Production: Maintains carbonation

Metal Processing

- Aluminum Extrusion: Maintains die temperatures

- Electroplating: Regulates bath temperatures

- Galvanizing: Controls zinc bath temperature

- Metal Finishing: Ensures proper cooling

Oil and Hydraulic Systems

- Hydraulic Oil Cooling: Prevents overheating

- Cutting Oil Cooling: Maintains optimal machining

- Quenching Oil Cooling: Controls heat treatment

- CNC Machines: Prevents thermal expansion

Construction Materials

- Concrete Batch Mixing: Controls water temperature

- Pipe Extrusion: Ensures consistent pipe properties

- Composite Materials: Regulates curing temperatures

How to Select an Industrial Chiller?

Only the right industrial chiller offers the ideal industrial cooling outcomes. Check these key factors that control choosing the right industrial chiller:

Make Tempcon Your Industrial Chiller Partner

Tempcon offers expert guidance in selecting and installing the ideal industrial chiller for your specific requirements. Our 40 years of experience, along with a diverse product portfolio, allow you to choose an energy-efficient, reliable cooling solution.

Contact us today for our technical support and turnkey industrial chiller solution.

Contact Us