The Cooling Companion

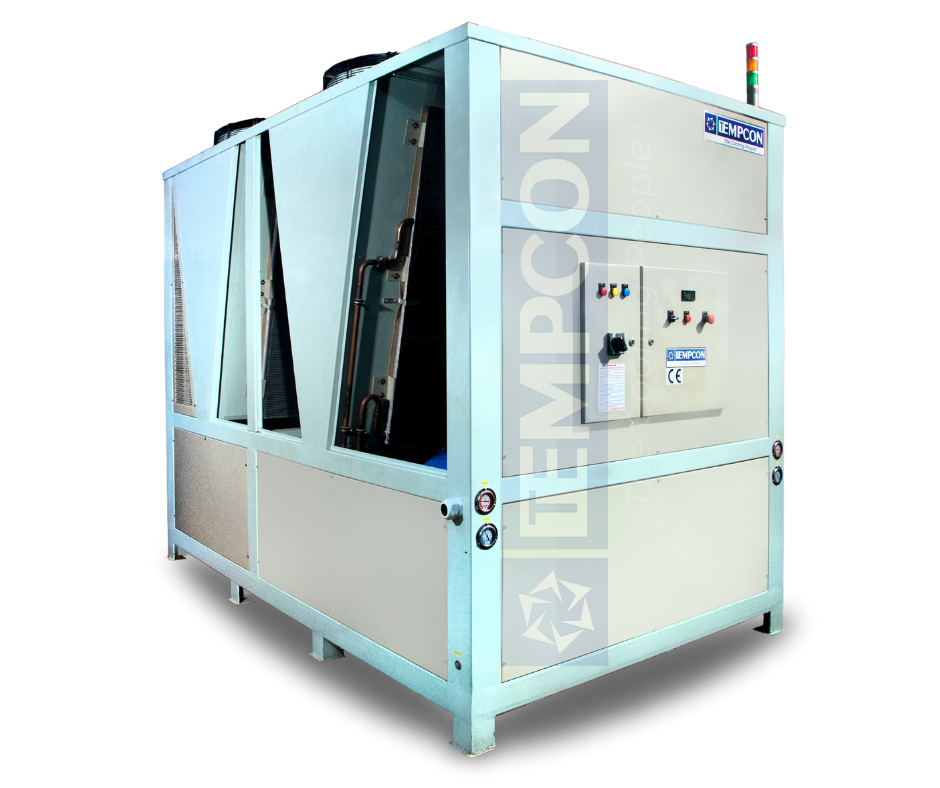

Tempcon: The Best Among Industrial Chiller Manufacturers In India

Tempcon brings state-of-the-art industrial chillers for your plants and factories. Say goodbye to high energy costs and inefficient temperature control. Embrace the all new industrial chillers that run on variable speed drives and use environment-friendly HFO refrigerants. Be the LEADER in your industry, be the CHANGE with our advanced Industrial Chillers!

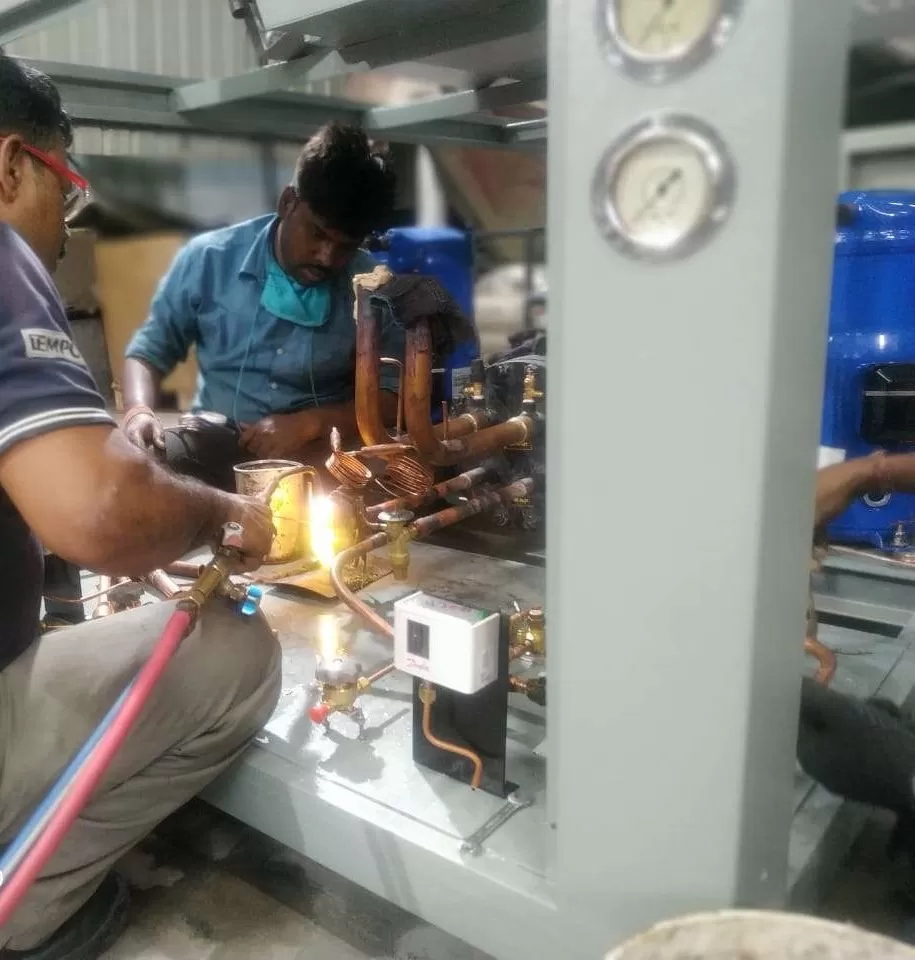

Easy Maintenance

Our chillers feature accessible and modular components for easy maintenance without disruption. These machines don’t require frequent maintenance as well. Set up and have peace of mind – that’s the Tempcon promise.

Intelligent Temperature Control

You don’t need to constantly optimise Tempcon chillers. These intelligent machines have inbuilt algorithms to detect the real time temperature of the facility. Equipped with these algorithms, the chillers auto-adjust the temperature.

Hassle-Free Installation

All our industrial chillers use microchannel condensers for higher energy efficiency and stainless steel pumps for better durability. What’s more! Say goodbye to remotes and knobs. Tempcon chillers come equipped with touch screens!

EFFICIENT COOLING

Efficiency is a major advantage of chillers we create, making them perfect for clients who are focused on saving energy and reducing operating expenses in their projects and installations.

The Tempcon Advantage: Most Reliable Industrial Chillier Manufacturers In India

OPERATIVE RELIABILITY

Highest reliability of our chillers achieved by intelligent engineering and assured through the use of time-proven mechanisms, maximum manufacturing precision, and thorough equipment testing.

ENVIRONMENTAL SAFETY

We pioneer in adopting numerous advanced technologies aimed at improving environmental safety, including safe refrigerants, within our chiller range, while adhering to energy efficiency regulations.

Just Fill Out The Form. We’ll Get In Touch!

The Tempcon Promise

Peak Industrial Performance With Tempcon Industrial Chiller

Tempcon industrial chillers provide best-in-class cooling mechanisms with superior after-sales support. Stay invested in your processes while we make sure that the temperature in your plant remains optimal during the entire lifecycle.

If you want your cooling system to provide constant temperature, then Tempcon is the way to go. Slash electricity bills and be assured of getting timely help from trained engineers whenever needed.

Sustainable Industrial Chiller | Future Proof Processes

Tempcon strives to make its offering more consumer-centric by playing a leadership role in sustainability. Our low-noise chillers are perfect for forward thinking companies that want to future-proof their manufacturing processes.

Governments across the world are coming up with stricter compliance in terms of environmental safety. In this scenario, it becomes necessary for businesses to keep their manufacturing processes compliant.

All our industrial chillers are ECO design compliant and use multiple safety mechanisms to keep both the environment and your workers safe. Upgrade your cooling system and see the difference.

Tempcon is the best industrial chiller in India, thanks to the international standards used to make Tempcon chillers. These industrial chillers follow the European Eco design directive. We strictly use environment-friendly refrigerants like R134A.

Tempcon manufactures all the major kinds of chillers. From water-cooled screws and scroll chillers to air-cooled screws and scroll chillers – we make and implement chillers with all kinds of mechanical attributes. We also manufacture reciprocating and VFD chillers and Industrial AC as well.

Tempcon Industrial Chillers can be used for any process cooling needs. Some applications include – food processing, pharmaceutical, chemical processes, plastic industry, power generation and more.

Industrial Chillers Explained: How They Keep Your Business Running Cool

In many industries, keeping equipment and processes cool isn’t just helpful. It’s essential. That’s where industrial chillers come in. They remove unwanted heat from machines, products, and even the air inside your facility. Chillers help keep things running smoothly in plastics, food processing, pharma, or data centers.

The Basics of Industrial Chillers: Four Main Parts

Compressor

This is the starting point. It compresses the refrigerant gas to boost its pressure and temperature so that it can carry heat through the system.

Condenser

The hot gas moves into the condenser. The heat from the gas is released into the air or water. The refrigerant cools down and turns into a liquid.

Expansion Valve

This part drops the pressure of the liquid refrigerant. That drop cools it down even more and gets it ready to absorb heat again.

Evaporator

The now-cold refrigerant flows through the evaporator. It absorbs heat from your equipment or process and turns it back into gas. The gas goes back to the compressor to repeat the same cycle.

How an Industrial Chiller Works: Step by Step

Compression

The refrigerant starts as a low-pressure gas in the compressor. The compressor increases its pressure and temperature.

Condensation

The hot gas moves through the condenser coils. The heat is pulled out by air or water, and the gas becomes a high-pressure liquid.

Expansion

The liquid refrigerant then goes through the expansion valve. Its pressure drops and cools into a mixture of cold liquid and vapor.

Evaporation

This cold mix of refrigerant liquid and vapor runs through the evaporator to absorb heat from industrial equipment or operations. The refrigerant then turns back into gas and heads to the compressor again.

Types of Industrial Chillers

Air-Cooled Chillers

These chillers use air to get rid of heat. They’re good in areas where water is limited. Air-cooled chillers are easier to install and maintain because they don’t need a cooling tower.

Water-Cooled Chillers

These chillers use water to remove heat. They tend to be more efficient in hotter climates or for bigger jobs. They do need a cooling tower and regular water treatment.

Smarter, More Efficient Systems

VFDs (Variable Speed Drives)

These advanced components let the compressor slow down or speed up depending on how much cooling you need. That saves energy when demand is low.

Smart Controls

These systems monitor temperature and adjust other components automatically. They help keep energy costs down to a considerable extent.

Need Help Picking the Right One?

Choosing the right chiller can cut energy use, reduce downtime, and improve overall performance. At Tempcon, our team takes the time to understand your process, your facility, and your goals. Then we help you select a system that fits both in size and cost. Reach out today for a free consultation, and let’s keep your operations running cool and efficient.