How Does a PAC Unit Work

A. The Fundamental Working Principle of a Precision AC

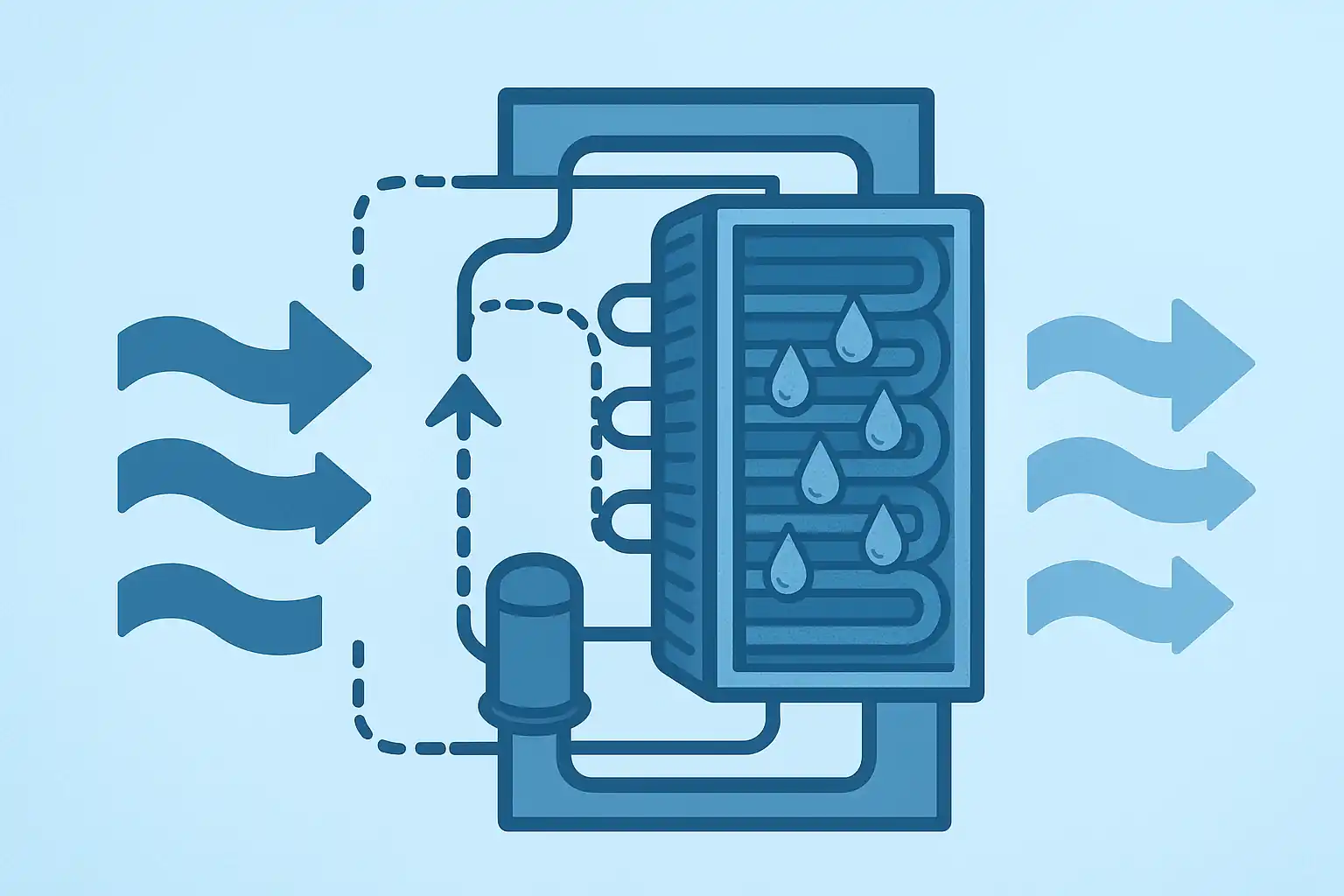

The basics remain the same. The PAC draws in warm air from the room. This air typically contains both sensible heat (the heat that increases air temperature) and latent heat (moisture content in the air).

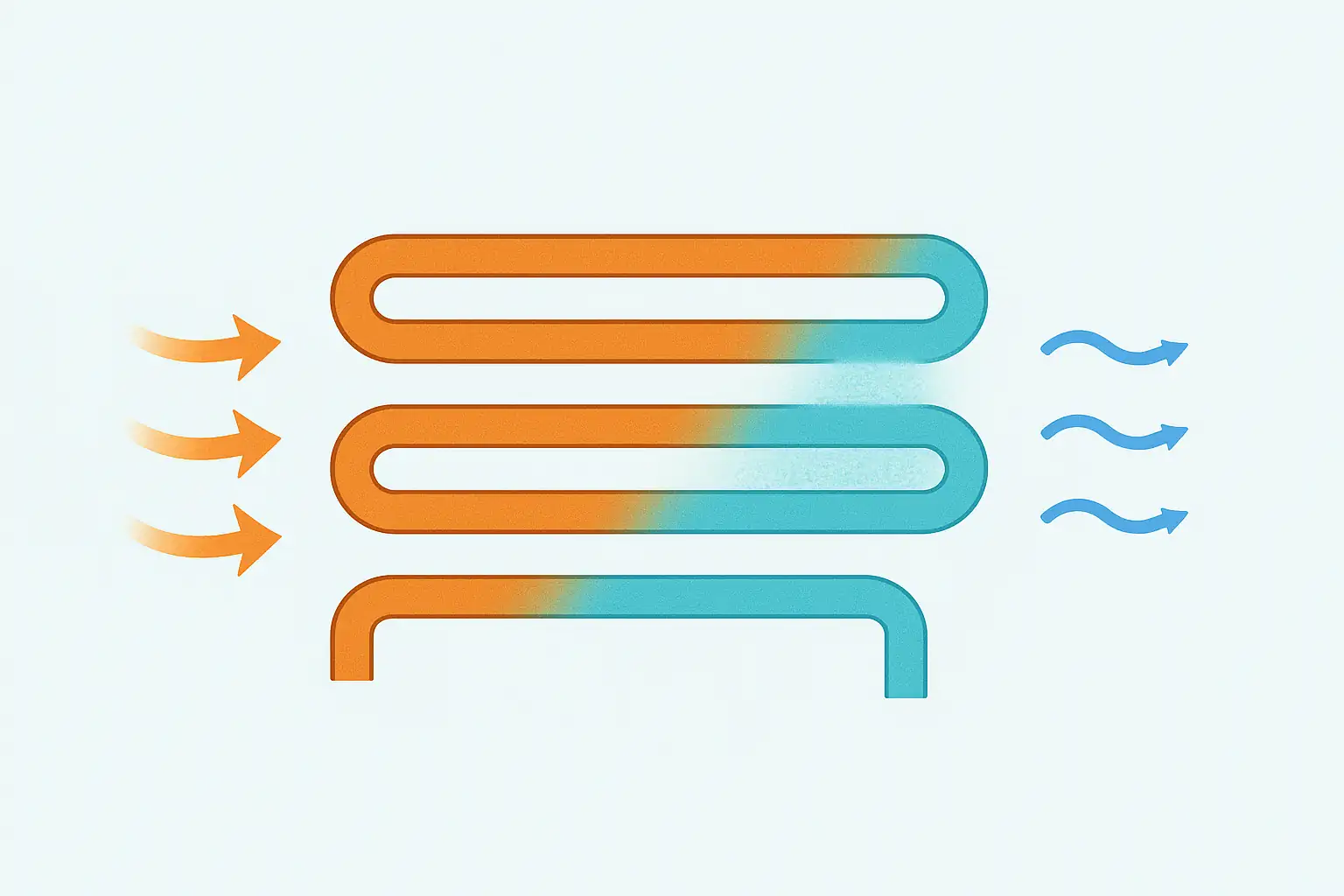

Warm Air Is Drawn Across The Evaporator

Refrigerant Turns To Low Pressure Gas Upon Heat Absorption

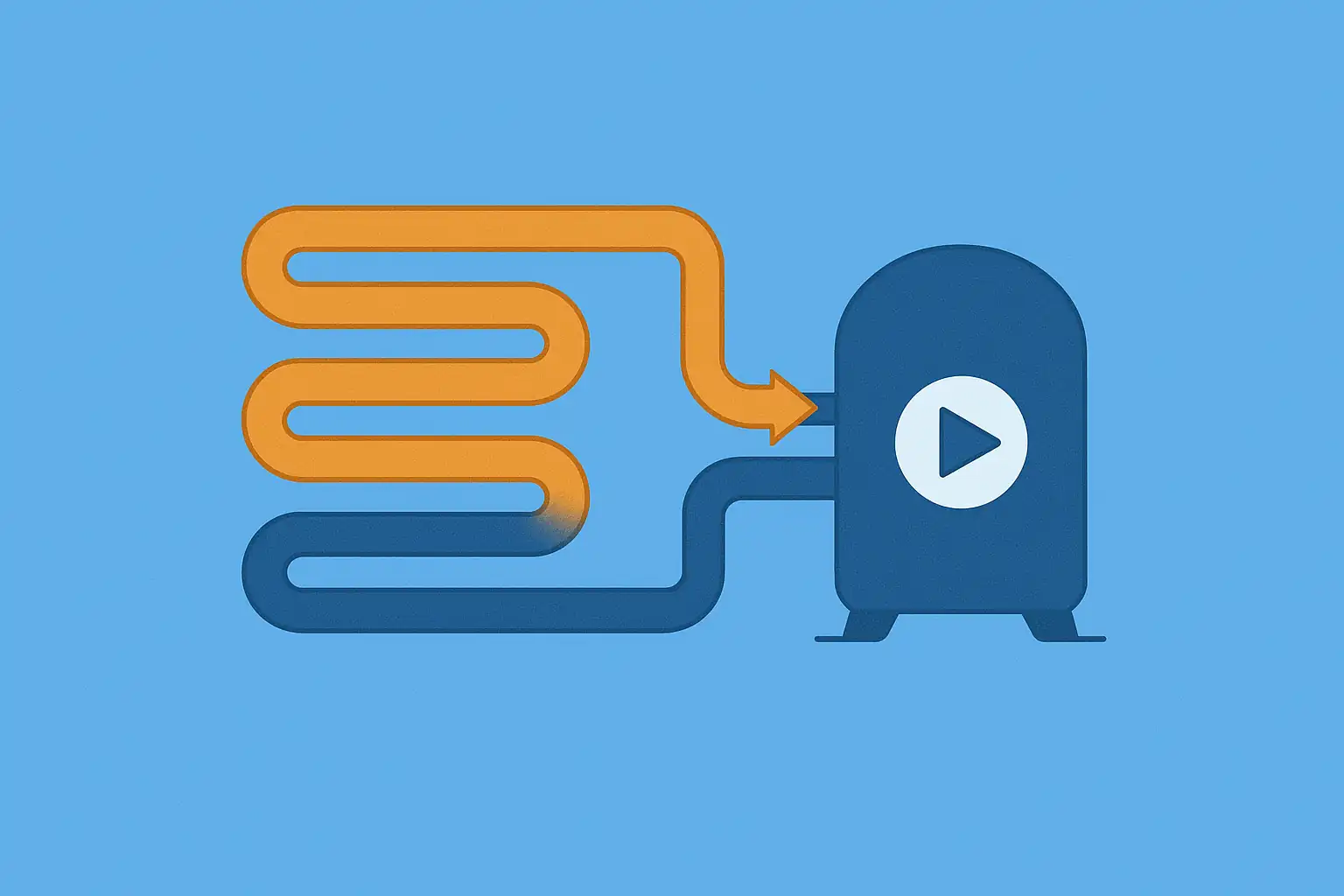

The Role of The Compressor

Heat Rejection Through Condenser

Refrigerant Condenses Upon Losing Temperature

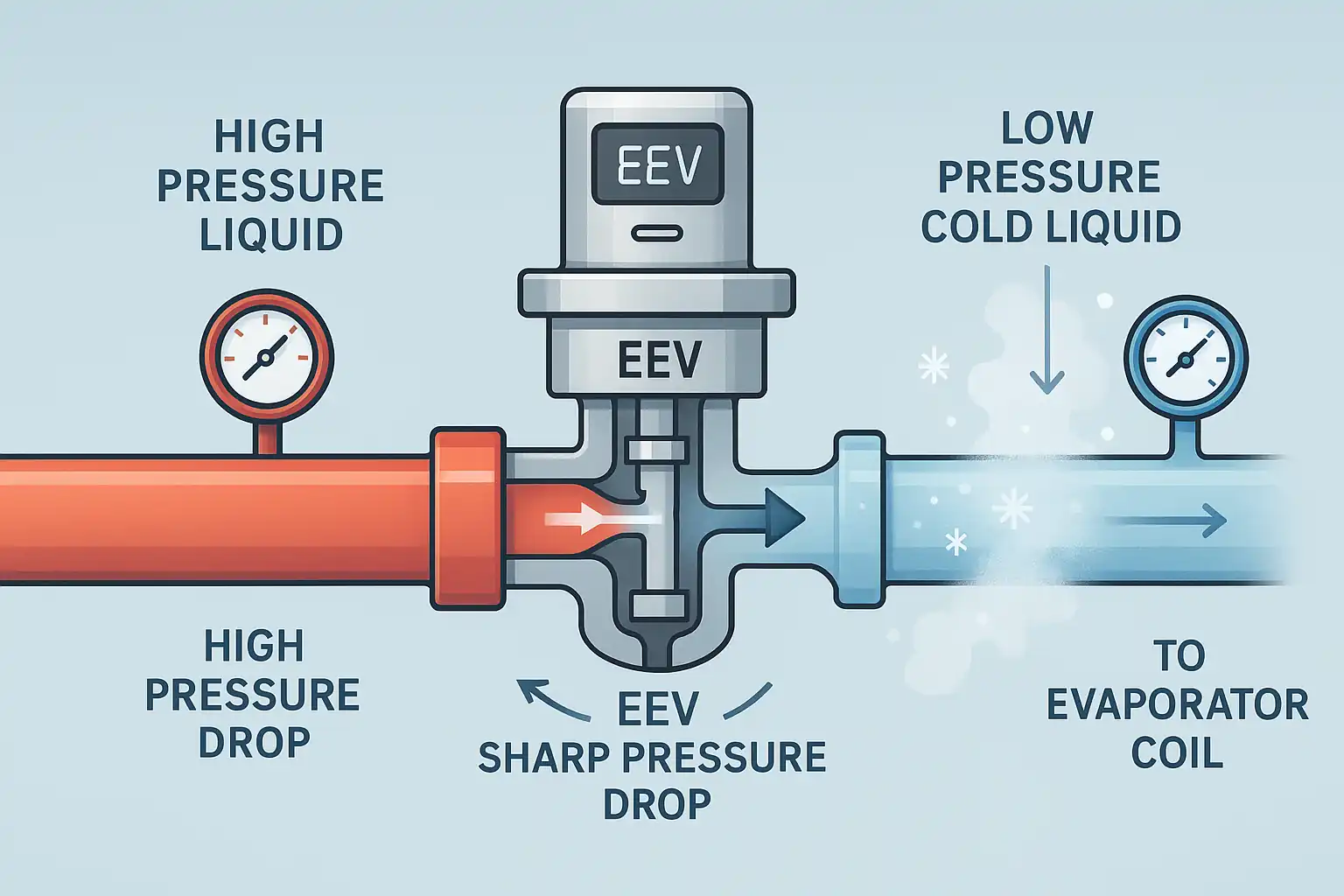

The Role of Electronic Expansion Valve

The Working Principle That Makes Precision AC a Precision AC

Tight Temperature Control

A Precision Air Conditioner is “precise” because it maintains a tighter temperature control – typically within ±1 °C – for data centers, labs, and telecom rooms. This is enabled by smart components, sensor logic, and design precision.

High Accuracy Sensors

PACs come with sensors that detect even nominal changes in temperature and provide real-time data input.

Intelligent Temperature Control

Algorithms (PID or adaptive) analyze sensor data to adjust:

- EC Fan Speed: Matches airflow to heat load. Prevents recirculation in hot/cold aisles.

- Compressor Speed: Digital compressors ramp up/down based on setpoint deviation – like self-adjusting logic.

- EEV Opening: Fine-tunes refrigerant flow and ensures vapor-only entry into condenser. Stable superheat is key.

Humidity Control

Humidity damages sensitive equipment. PACs maintain RH between 40–55% using:

- Electric/hot-gas reheat coils

- Steam humidifiers

N+1 Configuration

Redundancy is non-negotiable. PACs are deployed in N+1 configuration:

- N: Number of units needed for load

- +1: Standby unit that auto-replaces any failure

Explore Tempcon Precision AC